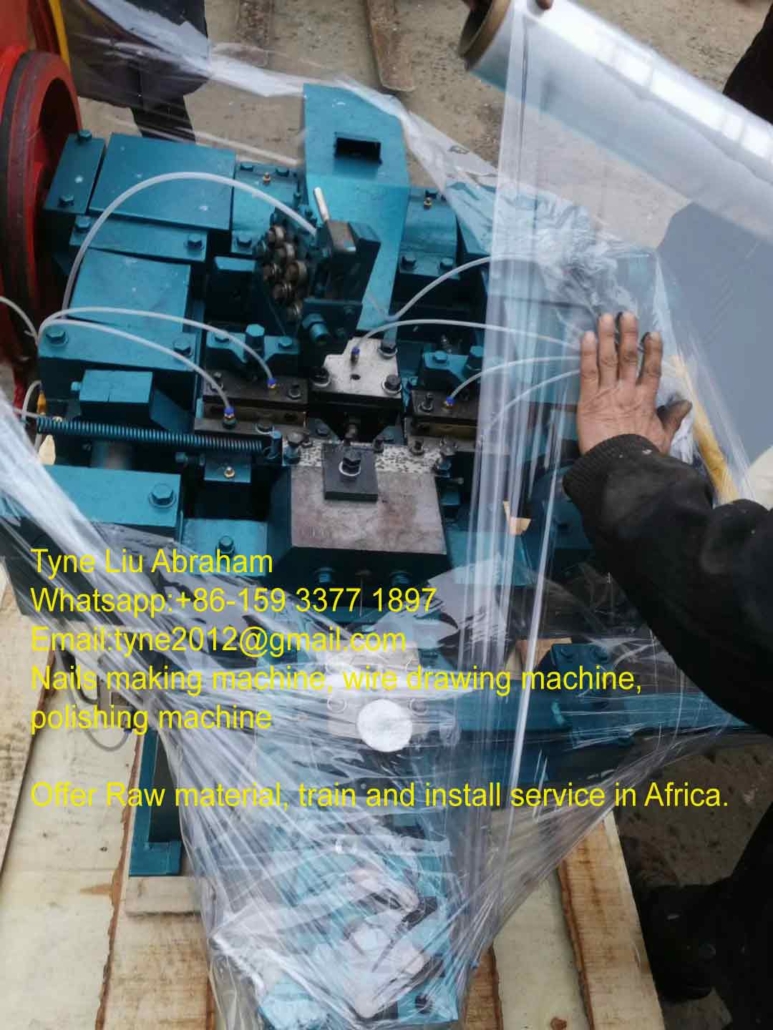

Twisted nail making machine

What is a twisted nail making machine? For us, there is no twisted nail machine. When we produce nails making wire, we can use wire drawing machines to make twisted shank during the wire drawing process.

TWISTED SHANK NAIL MAKING MACHINE

Twisted shank Wire nail making machine (nail producing machine, nail producing equipment, nail manufacturing machine) is the machine to make wire nails (common iron wire nails).

WHAT IS THE TYPE OF COMMON NAIL ?

As we know, the common wire nail is a normal nail. We can see in daily life. It has a big checked head and a smooth/twisted/ring shank body. The wire nail machine will punch the wire to form the heads. We can write the brand name or words on the punching pin, after punching, the letter left on the head. And the head has a circumferential edge defining a complete circle; characterized in that the center of the head is radially offset from the axis of the shank. We use the knives to cut the wire and form the nail tip. Which is very sharp, like a diamond.

SPECIFICATION FOR TWISTED NAILS MACHINE

| Model | Z94-1C | Z94-2C | Z94-3C | Z94-4C | Z94-5.5C | Z94-6.5C |

| Max. dia. of nail | 1.6mm | 2.8mm | 3.5mm | 4.5mm | 5.5mm | 6.5mm |

| Min. dia.of nail | 0.9mm | 1.2mm | 1.8mm | 2.8mm | 3.1mm | 4.5mm |

| Max. Length of nail | 25mm | 50mm | 75mm | 100mm | 150mm | 200mm |

| Min. length of nail | 9mm | 16mm | 30mm | 50mm | 80mm | 100mm |

| Motor power Phase | 1.5kw | 2.2kw | 3kw | 4kw | 5.5kw | 11kw |

| Nail making speed | 450pcs/min | 350pcs/min | 320pcs/min | 260pcs/min | 200pcs/min | 180pcs/min |

| L*W*H | 1.5*1.3*1.2m | 1.7*1.3*1.4m | 2.0*1.4*1.4m | 2.2*1.6*1.65m | 2.5*1.6*1.5m | 3.5*1.9*1.8 |

| Weight | 1.2tons | 1.45tons | 1.8tons | 2tons | 2.3tons | 5.5ton |

VIDEO FOR TWISTED NAIL MANUFACTURING PLANT

As we can see by below video, nails are made from low carbon metal wire. The wire is feeding into nail-making machine on the reel. Each machine can punch 450-180 nails per minute. Then we can make the nail ring shank, twisted shank by roll machine. Or just polish it by polishing drum about 2 hours.

HOW MANY MACHINE NEED IN NAIL MAKING PLANT?

- So how to start nail making business? The nail making machine line including:

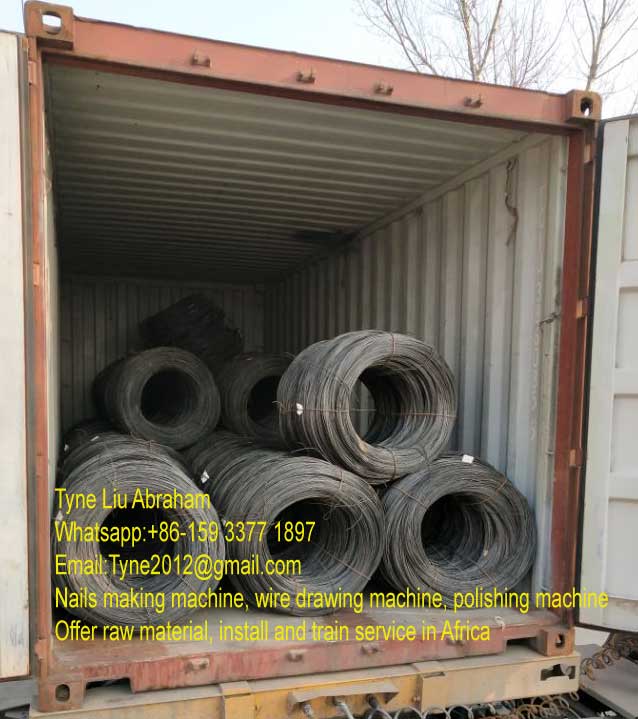

- 1 SET Wire drawing machine to produce low carbon wire rod Q195, 6.5mm-1.5mm,

- 3 SETS Twisted Nail making machine by twisted wire, (nail making machine equipment)

- 1 SET Wire nail polishing machine and some auxiliary small machines. (nail washing machine)

NAIL MANUFACTURING OPERATION ROCESS:

FIRSTLY WIRE DRAWING

The first step and its off-set involve shell peeling followed by descaling the low carbon iron wire rod 6.5mm. While drawing, you can use drawing die to form the wire rod to the diameter/thickness/gauge/mm that your market need.

THE SECOND, NAIL MAKING

We can use the nail making machine and it’s auxiliary components to make the different size/length/thickness/gauge/mm nails. Feed different thickness wire to nails making machine. Punch to form the head and cut to get the sharp tip. One set machine can make about 1000kg per day. Different type machine, the daily output different. We can give you a practical solution after you tell your production capacity.

NEXT IS NAILS POLISHING

While Twisted nail making machine punching the wire to form a cap, some oil will be left in nails. So the wire nail need polishing. It is not necessary to use the nail polishing machine. Some countries no need polishing, also can sell well. Your opinion for polishing. We can mix nails with sawdust AND wax in the machine drum to achieve the required brightness.

HOW TO PREPARE NAILS MAKING WIRE?

- The metalworking process can reduce the cross-section of a wire. Wire drawing has many applications. It is not entitled to nail making industry.

- Use a nail machine to pull the wire through a series of dies, which can make the wire cross-section smaller.

- We can put the different thickness wire drawing dies in the box. Then the drawing dies can form wire into different thickness/gauge/mm. As we know the nail thickness. The wire drawing machine pulls the wire through smaller dies. Then it can decrease the diameter and increase the length.

- The nail producing process comprises wire drawing, molding, and polishing. We should check the diameter of your local market nails to know the thickness.

WHAT IS THE RAW MATERIAL OF NAILS?

The raw materials of nails are low carbon steel wire rod. Also can use Aluminum, copper, brass, bronze. Some also ok with stainless steel, nickel silver, zinc, and iron wire. Galvanized concrete nails have high corrosion resistance. Blue concrete steel nails are subjected to a flame to give them a bluish oxide finish. That provides a certain amount of corrosion resistance. Cement-coated nails are actually coated with a plastic resin to improve their grip. Some brads are given a colored enamel coating to blend in with the color of the material they are fastening.

HOW TO MAKE THE COMMON WIRE NAILS?

- Wire is drawn from a coil and fed into the nail making machine where it is gripped by a pair of gripper dies. The shape of the head of the nail has been machined into the end of the dies.

- While the dies clamp the wire in place, the free end of the wire is struck by a mechanical hammer. This deforms the end of the wire into the die cavity to form the head of the nail.

- With the wire still clamped in the dies, a set of shaped cutters strike the opposite end of the nail, forming the point and cutting the nail free from the rest of the wire coming off the coil.

- The dies open and an expelling mechanism knocks the nail into a collection pan below the machine. The free end of the wire is drawn from the coil and fed into the machine. The cycle then begins again.

WHY THE NAILS NEED POLISHING?

- Sometimes, we put hot caustic soda/wax in a rotating barrel.

- Nail forming machine has an oil feeding system to protect working well. So some oil drops to the nails shank.

- We use a nail polishing machine to remove oil. And clean up some small metal scraps, or nippings, that might be clinging to the nails.

HOW MANY KINDS OF NAIL SURFACE TREATMENTS?

- Before packing in carton or bags, we need make common nails more shining and bright finish.

- Put the nails in a rotating drum of sawdust to polish the surface of the nails.

- Some need heating treatment with a flame before blue painting and zinc coating.

- Galvanized nails are dipped into a tank of molten zinc in a process called hot-dip galvanizing. A zinc coating may also be applied by heating the nails to about 570°F (300°C) in a closed container filed with a powder composed of zinc dust and zinc oxide. Other coated nails are either dipped or sprayed to obtain their final finish.

HOW TO CONTROL/INSPECT THE NAIL QUALITY?

Once the nail making machine forms the cap, the coil needs to be polished for it to qualify as a nail. The nail polishing machine makes the nail brighter by mixing it with sawdust and stirs it synchronously. Hence will help you achieve a required degree of brightness.

Raw materials must meet certain standards for chemical composition, yield strength, hardness, corrosion resistance and other properties. These are usually certified by the company supplying the wire, and may be independently checked by the nail manufacturer.

During manufacture, nails must also meet certain specifications regarding dimensions and properties. These are achieved using a method known as statistical process control, which periodically samples the dimensions and properties of the nails being produced and evaluates any changes through statistical analysis techniques.

We are a professional nail manufacturing machine manufacturer, providing a variety of nail manufacturing equipment and auxiliary machinery, contact us for the best offer and more information.

QUESTIONS ABOUT WIRE NAIL PRODUCING MACHINE

- Q: Can I use one Cut nail making machine to make different size nails?

- A: Of course can, for example, you can buy one Z94-4C to produce 1-4inch nail, to make different size, just change the nail mould is ok. But for professional nails making factories, we use as the different types to make different sizes, more efficient.

- Q: How many are the material waste during the producing?

- A: The rate of the production waste is less than 3 %, for example, 1 ton wire can make around 970 kg nails.

- Q: What is the spareparts for Cut nail making machine?

- There are three based spare parts of the wire iron nail making machine: nail mould, nail cutter, pin punch.

- Q: Does the wire drawing machine is a must equipment?

- A: No, if you buy the drawn wire ( like 3.4mm ) directly to make nail then no need this machine.

- Q: What is capacity of the wire drawing machine ?

- A: If you select 3 drums, from 6.5mm wire drawing to 5.5mm, the output is around 800kg per hours.

FURTHER NECESSARY TOOLS AND SPAREPARTS

- Wanted to know rate for this machine? Check here for BEST WIRE NAIL MAKING MACHINE.

- Complete set price required: catch us by whatsapp or Email, we will give your suitable quotation further.

- Warranty period of machine: 1 year

- Semi automatic or automatic

- Service facilities: as following

- Wire drawing machine for different thickness nails making wire.

- Welded machine for connecting two strands wire together.

- Polishing machine for making iron wire nails more smooth, removing the rust and rags.

- Grinding Machine for nail knives sharp and knife-edged, keen.

- Nails mold for shaping nails types.

- Punch pin for nails head.

- Gripping Dies to hold nails wire.

- Cutting dies to make diamond points, round shank.

- Header dies to make chequered or plain heads.

- If you need more infomation for common nail making machine price, contact us.