Nail making automatic machine

Common wire nail making automatic machine is a small investment, huge profit business in Africa. Can make various types of nails. Automatically feeds raw material and Various models available. The nail making machine is used for producing various normal nails and special nails. And the assortment of our products is complete. It has wide applications, simple operation, and reliable running. We can supply various machine fitting and necessary fine auxiliary to you.

NAIL MAKING AUTOMATIC MACHINE FOR AFRICA

- West African Region – Sierra Leone / Gambia / Ghana / Liberia / Togo / Benin/ Congo / Cameroon / Ivory Coast / Burkina Faso / Gabon / Angola.

- South & South East Africa Region- South Africa / Mozambique / Malawi / Zimbabwe / Zambia / DR Congo / Rwanda / Uganda / Burundi/ Tanzania/ Kenya.

- IOI Region- Madagascar / Sri Lanka / Comoros / Mauritius / Seychelles / Maldives/ Réunion Island.

- Caribbean Region – Haiti/Trinidad & Tobago/ Dominican Republic/ Brazil/ Jamaica/ Guyana.

HIGH SPEED NAIL MAKING automatic MACHINES LIST

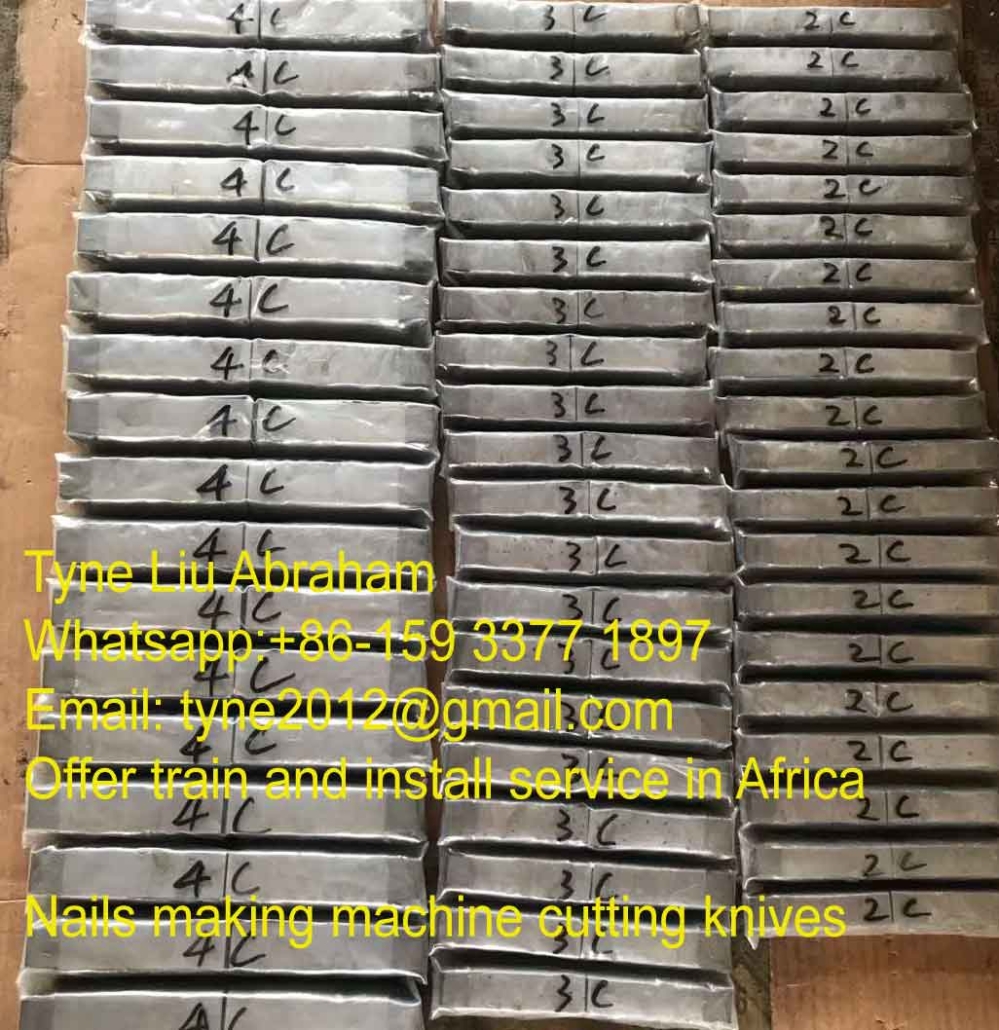

| Model | diameter of nails | length of nails | Designed speed | Motor | Dimension | Weight |

| Z94-1C | 0.9-1.6mm | 9-25mm | 450pcs/min | 1.5kw | 1.5*1.3*1.1m | 1.2tons |

| Z94-2C | 1.2-2.8mm | 16-50mm | 380pcs/min | 2.2kw | 1.7*1.3*1.4m | 1.45tons |

| Z94-3C | 1.8-3.5mm | 30-75mm | 320pcs/min | 3kw | 2.0*1.4*1.4m | 1.8tons |

| Z94-4C | 2.8-4.5mm | 50-100mm | 260pcs/min | 4kw | 2.2*1.6*1.6m | 2Tons |

| Z94-4C (2) | 2.8-5mm | 50-120mm | 260pcs/min | 4KW | 2.3*1.6*1.3m | 2.1Tons |

| Z94-5.5C | 3.8-5.5mm | 75-150mm | 220pcs/min | 5.5kw | 2.5*1.8*1.5m | 2.3tons |

| Z94-6C | 4-8mm | 100-200mm | 180pcs/min | 11KW | 3.4*1.9*1.5m | 5tons |

| Z94-6A(2) | 3-6.5mm | 175-400mm | 80pcs/min | 15kw | 3.5*1.9*1.8m | 8tons |

| Z94-8A | 5-10mm | 180-320mm | 120pcs/min | 22kw | 6*2.1*1.9m | 10tons |

ADVANTAGE OF AUTOMATIC NAIL MAKING MACHINE

- Very low noise,the noise will not let people feel uncomfortable .

- Auto lubrication: just add the lubricant into the small oil tank,then the machine can lubricate machine parts automatically.

- Bearing structure and longer lifetime.

- High capacity and production process automation

- Low noise

- Automatic lubricator

- High dimensional accuracy of produced nails

- Automatic wire feeding system

- Alarm system and automatic shutdown system in case of failures of wire feeding system, equipment overload, low lubrication, and any defects

- Closed construction frame

- Very High level of occupational safety for nails making automaticly.

- Unique patent, two-time heading, double-dies and double-punches structure

- Bigger nail heads can be easily gotten

- Nail heads are always very round and in the center.

- Nail head without knock marks, consistent and good looking

- Uniform thickness of the nail cap diameter.

- Hollow design nail clamping dies, no small head, no ash blocking, no clip crumbs, no cracking, no frequent dies demolition.

- Shorter stroke, lower mechanical wear

- High precision, nail cutters work without touch, low tool wear.

- One set of cutters’ cutting times up to 10 million times

- Feeding and rewinding structure for HIGH SPEED AUTOMATIC NAIL MAKING MACHINES

- High -precision feeding device. The error of each nail length is controlled within 0.3mm

- Unique wire feeding and retreating combination, each nail through the wire feeding, cutting, wire retreating, three mechanical action, the nail will be completely separated from the nail shank to ensure quality.

- For the machine with cover, we adopt good sound insulation material, which can effectively reduce the noise.

- Nail cutter holder adopts pendulum structure

Other machines for nails making plants.

- Sharpening dies: this machine is to sharpen the head of steel wire before it is feed into the wire drawing machine,the principle of the drawing machine is that using different size of drawing dies,for example,to draw steel wire of 6.5 mm to 5.8 mm,we can use a drawing die of 5.8mm,sharpen the head of 6.5mm steel wire less than 5.8 mm first,then put the head into the die,then fix the head of the wire to the wire drawing machine,then start pulling.after the wire come through the die,all the wire becomes diameter of 5.8mm.

- Nail knife grinder: because after 1-2 days cutting,the nail knife installed on the wire nail making machines will become blunt,then you can use the nail knife grinder to grind the nail knife to make it sharp again.

- Connecting welding machine: in case the wire breaks during drawing,you can use the butt welding machine to weld the broken wire together ,then continue the drawing.without this machine,if the wire breaks,you need to sharpen the wire head again and do all things from the start.

- Standard Accessories: Electric Motor, Starter, Belts, One set of Tooling, Wire Stand and Hand Operated Lubricating Pump

- Optional Accessories: Additional sets of Tooling (Set of Gripping Dies, Cutting Tools and Header Dies)

- Gripping Dies: Machines are provided with round dies having 8 or 10 nail holding grooves

- Cutting Die: For cutting nails and making point after the head & shank are formed Diamond, Chisel, Round, Long or Blunt shaped Points can be made by grinding the tools appropriately

- Header Dies: Used for formation of nail head Chequered or Plain Heads can be formed with these dies

AUXILIARY EQUIPMENT:Nail Polishing Drums (with motor, starter and belts)