China nail manufacturing machine

We are a China common iron wire nail manufacturing machine supplier. Located in Hebei Province, which is very famous for wire products and iron nails products.

Features of the wire nail making machine

Z94-3c is popular for nails making purposes. This type can make from 40mm-80mm, which is huge demand in building material market. Z94-4C series is our new designed product with many advantages.

- NAIL MANUFACTURING MACHINE Very low noise, the noise will not let people feel uncomfortable .

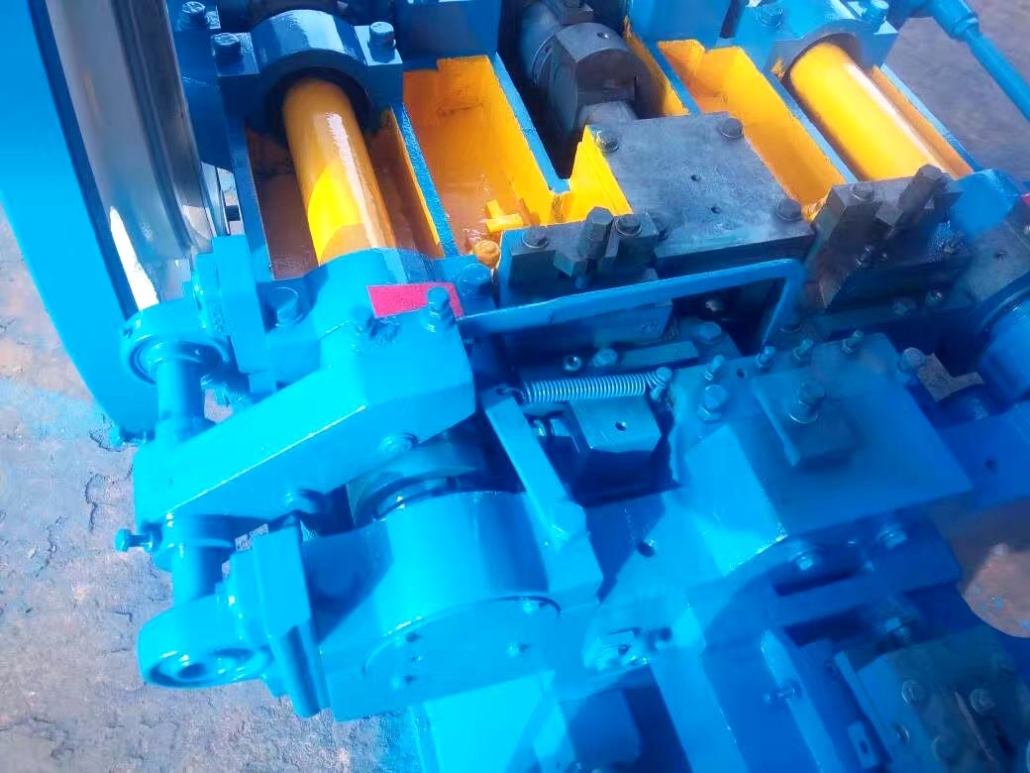

- wire nail making machine main parts(Shaft, Cam, Gear) are made of high grade steel with professional heat treatment to ensure nails machine have longer working life and less time maintenance.

- Auto lubrication: just add the lubricant into the small oil tank, then the machine can lubricate machine parts automatically.

- Bearing structure and longer lifetime.

- Each wire nail making machine will supply related spare parts of nail mould ,nail knife and punch pin, ect .

Technical Data of nail manufacturing machine

| Model | Z94-5C | Z94-4C | Z94-3C | Z94-2C | Z94-1C |

| Max. dia. of nail | 5.5mm | 4.5mm | 3.1mm | 2.8mm | 1.6mm |

| Min. dia. of nail | 3.8mm | 2.8 mm | 1.8 mm | 1.2 mm | 0.9 mm |

| Max. Length of nail | 150mm | 100mm | 75mm | 50mm | 25mm |

| Min. length of nail | 80mm | 50 mm | 30mm | 16mm | 9mm |

| Motor power | 5.5kw | 4kw | 2.2kw | 2.2kw | 0.8kw |

| Nail making speed | 220pcs/min | 260pcs/min | 320pcs/min | 350pcs/min | 450pcs/min |

| L*W*H | 2.5*1.8*1.5m | 2.2*1.6*1.65m | 2.0*1.4*1.4m | 1.9*1.356*1.4m | 1.55*1.3*1.1m |

| Weight | 2.2tons | 2tons | 1.5 tons | 1 ton | 750kg |

Whole wire NAIL MANUFACTURING MACHINE MAKING PROCESS

The whole process of nails production line: wire drawing — nails making —polish — nails packing

- Wire drawing machine — to draw the 6.5mm/5.5mm wire diameter to the smaller wire size diameter to make nails as your required such as 4.1mm, 3.4mm, 3.1mm, 2.5mm etc. wire diameter

- Automatic wire nail manufacturing machine — feed the drawn wire into nail making machine to make nails.

- Polishing machine — to polish finished nails to remove the thron and dust and make nails more black and shiny.

- wire nails Packaging— pack the nails in cartons or plastic bags, or kraft bag in 5kg, 10kg, 15kg, 20kg, 25kg nails, etc.

The function of the nail making machine is to make the common iron wire nails into different sizes through adjusting the nail making machine. It needs to put the suitable nails making wire diameter into the entrance of the nail making machine, then start the nail making machine, it will finish nail making automatically.

For our nail making machine, it is strengthened type, the frame is more heavy to ensure the fixedness of frame after tension. we pay more attention to every small parts details, all these small details ensure the best quality of the nail making machines so that it can run for many many years without any problem.

wire nail making machine Spareparts:

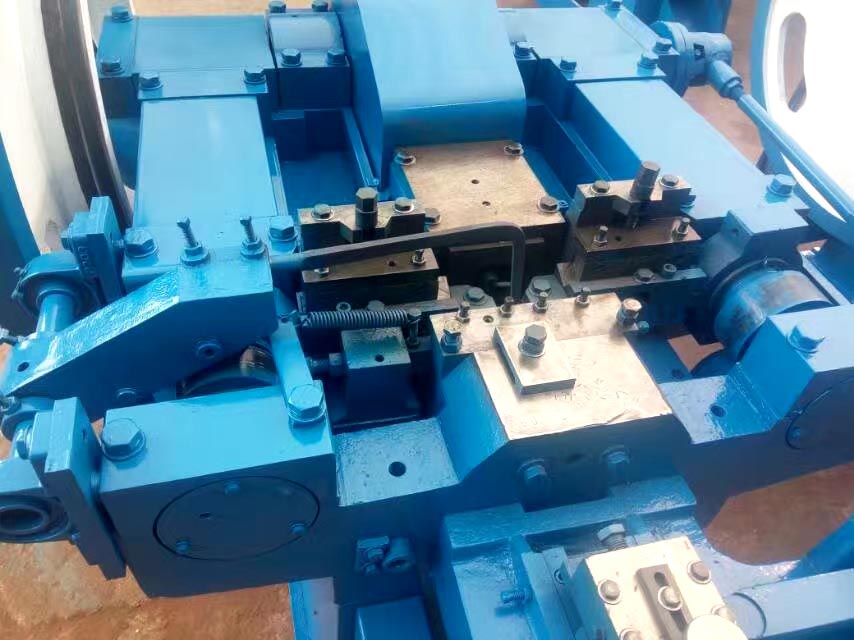

- nail mould/Grip Die/Gripping Dies: Machines are provided with round dies having 8 or 10 nail holding grooves, to clamp the wire for the nail knife to cut, to make different diameter nails, it needs to change different nail mould.

- Nail cutter/Nail knife: to cut the steel wire and make the nail point. For cutting nails and making point after the head & shank are formed Diamond, Chisel, Round, Long or Blunt shaped Points can be made by grinding the tools appropriately

- Header die/Pin Punch/ Hammer: Used for formation of nail head, Chequered or Plain Heads can be formed with these dies to make nail head. And also nail head can be customized with customer’s simple logo.

What we can do for you

- Help clients to set up their own small business through common nails making manufacture.

- Not only supply qualified machines, but also offer satified service.

- Technical support from China and Africa directly.

- Chinese masters.

- Train your team in our African manufactures.