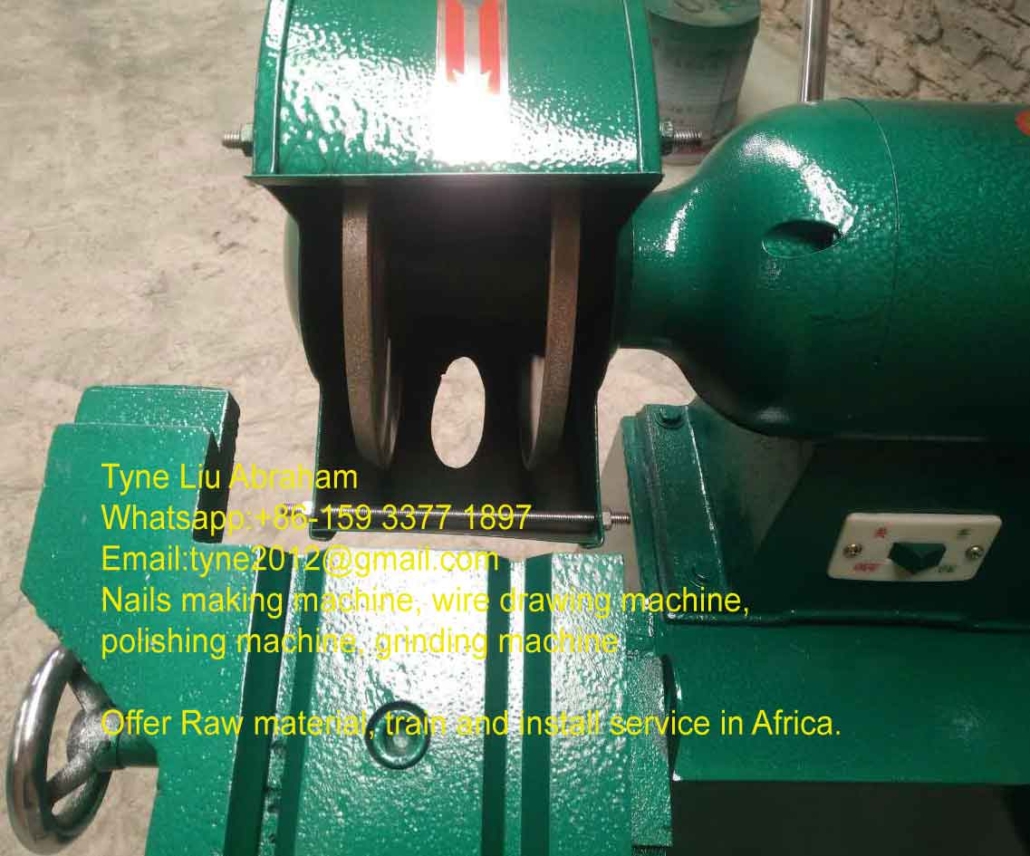

Grinding machine

What is the usage of the grinding machine? Characteristics of nail cutting knife grinding machine. People use it with nail making machine together. Model AM500 nail cutter grinder machine is specially designed for grinding.

GRINDING MACHINE FOR NAIL MAKING KNIFE

And sharpening tungsten carbide-tipped cutters and punches with a diamond wheel. It is equipped with a semi-automatic control device. Which permits uniform and accurate grinding jobs.

- Grinding machine is used for grinding alloy knives in nail-making factories. We use resin and diamond wheels to assemble the nail grinding machine.

- Our design of the body of the knife sharpener is changed from the original bulky cast iron. And loose frame structure to the steel plate closed welding structure. Improve the collective strength, increase and extend its service life.

- The collective of the steel plate is metal materials. After welding, we can guarantee its reliability and stability.

- Amigo brand grinding machine swing angle of the grinder head is 30 degrees.

- The original design of the swing angle is greater than 90 degrees. Which makes it easy and fast to work up and down and replace the grinding wheel.

QUICK DETAILS OF GRINDING MACHINE

- Condition: New

- Type: Surface Grind Machine

- CNC or Not: Normal

- Place of Origin: China

- Brand Name: Amigo Machinery

- Voltage:380V or as required

- Dimension(L*W*H):800*1000*500mm

- Certification: CE

- Weight (KG):120

- Power (kW):0.75

- Warranty:2 years

- Size: 800*1000*500mm

- Weight:120KG

- After-sales Service Provided: Video technical support, Field maintenance and repair service, Engineers available to service machinery overseas

- Applicable Industries: Building Material Shops, Manufacturing Plant, Construction works

- Color: Optional

- Title: Nail Making Machine Tool Cutter Grinder to Sharpen Cutter Knifes

- Key Selling Points: Automatic

- The diameter of grinding wheel: 200mm

- Motor power: 0.75kw

- Usage: Cutter Grinder Machine

Z94 NAILS MAKING MACHINE

set up common nails manufacture | roofing nails factory in Africa

| Technical data | Z94-1C | Z94-2C | Z94-3C | Z94-4C | Z94-5C | Z94-6C |

| Max Diameter | 1.6mm | 2.8mm | 3.4mm | 4.5mm | 5.5mm | 6.5mm |

| Min Diameter | 0.9mm | 1.2mm | 1.8mm | 2.8mm | 3.7mm | 4.5mm |

| Max Length | 25mm | 50mm | 75mm | 100mm | 150mm | 200mm |

| Min Length | 9mm | 16mm | 30mm | 50mm | 80mm | 100mm |

| Design capacity | 450pcs/min | 350pcs/min | 320pcs/min | 280pcs/min | 200pcs/min | 160pcs/min |

| Motor Power | 1.5kw | 2.2kw | 3kw | 4kw | 5.5kw | 11kw |

| Weight | 900kg | 1200kg | 1400kg | 2000kw | 2500kg | 5000kg |

| Overall Dimension | 1.4*1*1.3m | 1.6*1.2*1.3m | 1.8*1.3*1.5m | 2.1*1.3*1.5m | 1.4*1.6*1.7m | 3.2*2.2*2.2m |

NAIL MAKIMNG MACHINE PLANT IN AFRICA

OTHER SPAREPARTS AND AUXILIARY EQUIPMENT

- Wire drawing machine and wire drawing moulds for different thickness nails making wire.

- Welded machine/Butt-welding machine for connecting two strands wire together.

- Polishing machine for making iron wire nails more smooth, removing the rust and rags.

- Grinding Machine for nail knives sharp and knife-edged, keen.

- Nails mold/nail mould for shaping nails types.

- Punch pin for nails head.

- Gripping Dies to hold nails wire.

- Cutting dies/nail knife to make diamond points, round shank.

- Header dies to make chequered or plain heads.

- If you need more information for the Guangzhou iron nail making machine, contact us.

- Wire Enter, wire straightener, wire feeder,

- Die box, cutter box, hammer, crankshaft, flywheel, electric motor, auto lubricating pump, start power.

- cover half, moving die, thickness.