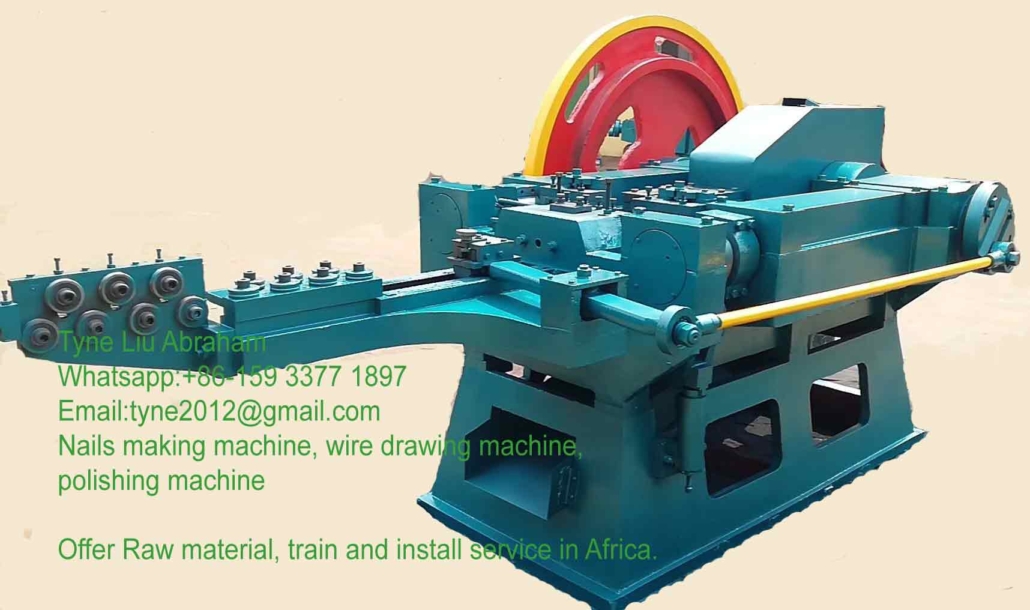

Nail making machine parts

What is nail making machine parts? What is the usuage of spareparts for machine? Amigo Machinery is a manufacturer of 1- 6 inch automatic nail making machine and nail making machine spareparts. Nail making machine contains many easy worn spareparts. Some parts required to replace after some time using.

NAIL MAKING MACHINE PARTS

Nail making machine is widely used in the manufacture of various nails. Such as roll nails, coil roofing nail, paper-row nails, blind rivets, small-cap nails, and iron wire nails. The unique setting structure makes the stability of the hat good and the 100% guarantee that the head is round and positive because it has the most headache problem for the boss of the aircraft, the first tail, the bent nail, and so on. Its the revolution of the traditional nail making process. This high-speed nail making machine used is faster and more energy-saving, and completely solves the problem of a small proportion of long and short nails, partial heads, nail caps, and nail shank rods. And can shape the nail point sharper with our nail cutter.

SPAREPARTS FOTO OF NAIL MAKING MACHINE

Nail making machine Spare parts including many different parts. Such as Nail Mould, Nail Cutter, Punch Bar, Wire reel, wire Stand for Nail Making Machine Spare Parts, Pin Punch, wire drawing dies.

NAIL MAKING MACHINE SPARE PARTS

- The Nail Mould can grip the raw material wire strand when the punching pin punches the wire to form the nail head.

- Nail Cutter knives can cut the wire into nail pieces by pieces with diamond tips/points.

- Punch Pin can hit/punch the wire to shape the nail head.

- Sharpening dies for wire drawing machine.

- Nail knife grinder: because after 1-2 days cutting, the nail knife installed on the wire nail making machines will become blunt, then you can use the nail knife grinder to grind the nail knife to make it sharp again.

- Gripping Dies: Machines are provided with round dies having 8 or 10 nail holding grooves

- Cutting Die: For cutting nails and making point after the head & shank are formed Diamond, Chisel, Round, Long or Blunt shaped Points can be made by grinding the tools appropriately

- Header Dies: Used for forming a nailhead Chequered or Plain Heads can be formed with these dies

- Nail Cutter and Die Grinder (supplied with a motor, Emery wheels, and Pedestal Stand).

- Optional Accessories: Additional sets of Tooling (Set of Gripping Dies, Cutting Tools, and Header Dies)

- Standard Accessories: Electric Motor, Starter, Belts, One set of Tooling, Wire Stand and Hand Operated Lubricating Pump.

- Imported gear: can work longer than normal.

- Thicken fuselage: Fuselage and a layer of steel. longer life.

- Wire feeding system: Multiple rolls can make the wire feeding speed adjustable.

- Spiral bevel gear: Imported gear can ensure better quality and more durable.

AUXILIARY EQUIPMENT FOR CHINA NAILS MAKING MACHINE

- Punch pin and nail Moulds.

- Connecting welding machine: in case the wire breaks during drawing, you can use the butt welding machine to weld the broken wire together, then continue the drawing. without this machine, if the wire breaks, you need to sharpen the wire head again and do all things from the start.

- Nail Polishing Drums (with a motor, starter, and belts)

- Wire Drawing Machine (WE OFFER A COMPLETE WIRE DRAWING LINE TO DRAW NAIL WIRE IN VARIOUS DIAMETERS FROM 6 mm or 5.5 mm WIRE RODS)

- Wire Drawing Dies used in wire drawing machines. There are many different sizes of the wire drawing dies, Such as 6.5mm,6.0mm, 5.8mm, 5.5mm, 5.3mm, 5.0mm, 4.8mm, 4.6mm, 4.2mm, 4.0mm, 3.8mm, etc. Then what thickness wire you want to make, just choose the related wire drawing dies.

- Nail Mould for Common Nails Making Machine and roofing nail making machine, used for all kinds of nails making.

- Wire Drawing Dies are made by diamond material. It’s very hard, no easy to broken. Dies can work for a couple of weeks in binding wire making, galvanized wire drawing, annealing wire drawing.

- Above is spare parts that are installed in the nail making machines. This machine is to sharpen the head of steel wire before it is feed into the wire drawing machine, the principle of the drawing machine is that using different size of drawing dies, for example, to draw steel wire of 6.5 mm to 3.8 mm, we can use a drawing die of 3.8mm, sharpen the head of 6.5mm steel wire less than 3.8 mm first, then put the head into the die, then fix the head of the wire to the wire drawing machine, then start pulling. After the wire comes through the die, all the wire becomes the diameter of 3.8mm.

HOW TO GET RAW MATERIALS?

- Normally, you can buy from the local market or steel company.

- If they can sell low carbon iron wire rod Q195,6.5mm/5.5mm. You can buy and use a wire drawing machine to draw to the thickness you need.

- If better, you can get the thickness nails making wire you need.

- And if local no wire rod and USED nails making wire, better import from China for any type of them.

- What should import, depend on how is the quantity you want to produce daily output.

- If quantity not much, you can just import nails making wire.

- But if your quantity huge, better buy a wire drawing machine to draw for yourself using.

- Then you can start a Fully automatic nail making machine imported from China to make nails. No need worry for Spare parts of nail making machine.

HOW WE FULLFILL YOUR ORDER?

- Any inquires will be replied within HALF DAY.

- Before-sale and after-sale service, overseas engineer service is available.

- All products have been strictly quality tests in our factory before packing.

- Free technical training, until customers can operate independently and qualified nail production produced.

- Guarantee time: one year since the machine was at buyer’s factory.

- We can ASSIGN our best technician to the buyer’s factory for installation, debugging, and training.

- Customer who buys our nail machine can enjoy the subsequent improvements in technology.

- Complete installation instructions, circuit diagram, manual operations, and machine layout.

- Timely reply for your machine questions, 24 hours support service.

1-6 INCH WOOD NAILS MAKING MACHINE

Amigo can supply you wood nails making machine from China. Z94 type 1c 2c 3c 4c 5c 6c nail making machine can produce wood nail, iron nail, common nails. How is nail making? We use nail making machine to produce wood nails. Our machine key components (crankshaft, cam, gear) are made of high-grade alloy steel.

- Plunger structure ensures high-speed, low noise, few impacting forces.

- Nail length may be freely adjusted by adjusting the eccentric disc.

- Nail diameter will be changed by dies.

We can supply different types of wood nails making machines for customers. If you want to start your nail making business, feel free to contact us. Z94-2C automatic nail making machine is used to manufacture 16mm to 50mm long nails. Its production rate is 350 pieces per minute. Our new developed High-Speed Automatic Nail Making Machine adopts a plunger and oil pipe lubricating structure so as to ensure the features such as high speed, low noise, and less impact. Especially, it can make the high quality of nails and other special nails with certain accessories. The assortment of our products is complete. We will supply various machine parts and necessary fine auxiliaries for you.

VIDEO OF WOOD NAILS MAKING MACHINE

LIST OF Z94 NAIL MAKING MACHINE DAILY OUTPUT

| Model | Z94-6C | Z94-5.5C | Z94-4C | Z94-3C | Z94-2C | Z94-1C |

| Max. dia. of nail | 8.0mm | 5.5mm | 4.5mm | 3.5mm | 2.8mm | 1.6mm |

| Min. dia. of nail | 4.0mm | 3.8mm | 2.8 mm | 1.8 mm | 1.2 mm | 0.9 mm |

| Max. Length of nail | 200mm(7 inches) | 150mm(6inches) | 100mm(4inches) | 75mm(3inches) | 50mm(2inches) | 25mm(1inch) |

| Min. length of nail | 60mm(2.5inches) | 75mm(3inches) | 50 mm(2inches) | 25mm(1inch) | 16mm(0.6inches) | 9mm(0.36inches) |

| Motor power | 7.5kw/11kw | 5.5kw | 4kw | 3kw | 2.2kw | 1.5kw |

| Nail making speed | 180pcs/min | 220pcs/min | 260pcs/min | 320pcs/min | 380pcs/min | 450pcs/min |

| L*W*H | 3.0×1.6×1.75m | 2.5*1.6*1.5m | 2.2*1.6*1.65m | 2.0*1.4*1.4m | 1.7*1.3*1.4m | 1.5*1.3*1.2m |

| Weight | 3 tons | 2.3tons | 2tons | 1.8 tons | 1.45 tons | 1.2ton |

| Output | 1500kg/8h | 1200kg/8h | 1000kg/8h | 800kg/8h | 400kg/8h | 80kg/8h |

HOW TO INSTALL SPAREPARTS TO A NAIL MAKING MACHINE

HOW CAN GET WOOD NAILS MAKING MACHINE IN AFRICA?

Our wood nail making machine is strengthened type. The frame is heavier to ensure the fixedness after tension. we paid more attention to the details of every small part, all these small details ensure the best quality of the nail producing machines. So it can run for many years without any problems.

You can import from Amigo Machine, which is the top 3 brands in China. Also, you can buy from your local market who selling machinery with a commission. Why do we need to know the China nail making machine price? Z94 type nails producing machines have different size, some can make big nails, some can make small nails. The performance of Automatic Z94 Type C New Generation Nail Making Machine is High-Speed and low Noise. Do you know how to operate an automatic Z94-C type used nail making machine and the machine price & worker salary? (nail machine, nail making machine, China nail making machine price).

HOW ABOUT QUALITY OF CHINA NAIL MAKING MACHINE?

The function of the Z94 Nail making machine used is to make the nails into different sizes by adjusting the nails making machine. It needs to put the suitable wire diameter into the entrance of the nail making machine. Then start the nail making machine, the machine will produce wood nails automatically. China’s price is not higher than the India machine. We really hope, clients can visit us if come to Hebei Province. Then we can show you what is the quality of Made in China.

TESTING OF NAIL MAKING MACHINE BEFORE DELIVERY

WIRE DRAWING MACHINE FOR NAIL MAKING RAW MATERIAL

WIRE POINTING MACHINE OPERATING VIDEO

BUTT WELDING MACHINE FOR WIRE DRAWING

GRINDERING MACHINE FOR NAIL CUTTER

Above is the related video of the nails making machine with all spare parts. Now hope you already know how to operate these nail making machine and AUXILIARY EQUIPMENT. Following, we introduce some spare parts of nail making machine.