Nail making machine South Korea

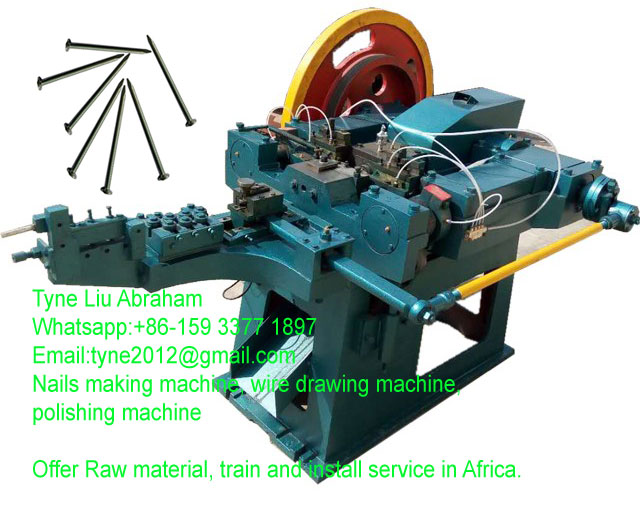

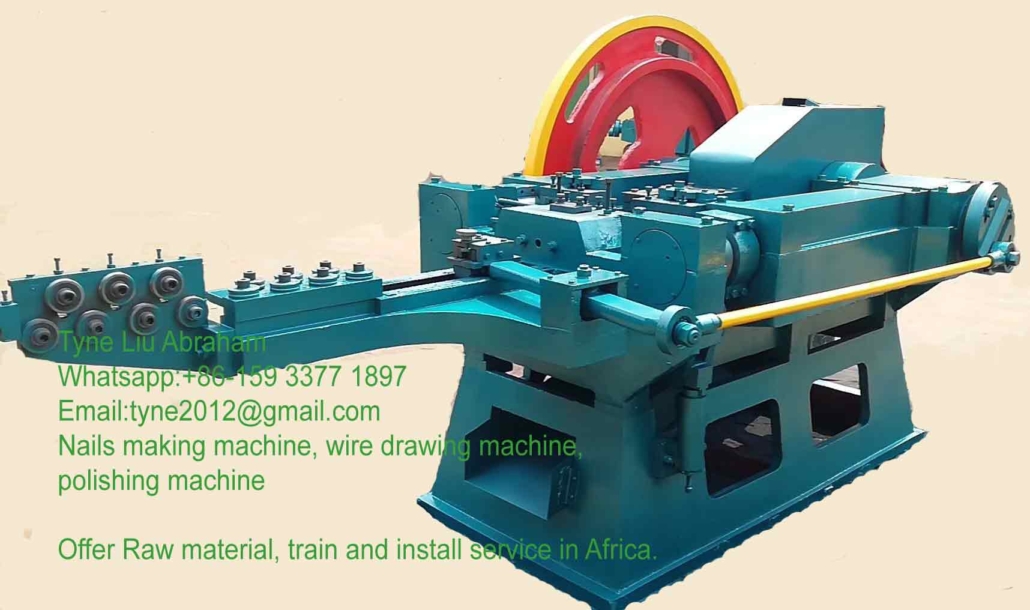

What is high-speed automatic nail making machine south Korea? This new type of machine adopts a plunger and oil pipe lubricating structure, to ensure the high working speed, low noise, and less impact. It has the features of advanced design, compact confirmation, and attractive appearance. It is easy and safe to operate.

1-6 inch Nail making machine in South Korea

The quality reaches the standard, the device has the characteristics of small size, flexible and convenient movement, low noise, low power consumption, and easy installation. Therefore, the project has become a project for enterprises, individuals, families, laid-off workers, and farmers to get rich.

FOTO OF SOUTH KOREA NAIL MAKING MACHINE

Based on economical practicability, achieving high technical content, convenient operation, and use, we had produced the nail making machine, the same with South Korea type. Which is cost-effective, energy-save, stable, and reliable performance.

LIST OF Z94 NAIL MAKING MACHIE DAILY OUTPUT

| Model | Z94-6C | Z94-5.5C | Z94-4C | Z94-3C | Z94-2C | Z94-1C |

| Max. dia. of nail | 8.0mm | 5.5mm | 4.5mm | 3.5mm | 2.8mm | 1.6mm |

| Min. dia. of nail | 4.0mm | 3.8mm | 2.8 mm | 1.8 mm | 1.2 mm | 0.9 mm |

| Max. Length of nail | 200mm(7 inches) | 150mm(6inches) | 100mm(4inches) | 75mm(3inches) | 50mm(2inches) | 25mm(1inch) |

| Min. length of nail | 60mm(2.5inches) | 75mm(3inches) | 50 mm(2inches) | 25mm(1inch) | 16mm(0.6inches) | 9mm(0.36inches) |

| Motor power | 7.5kw/11kw | 5.5kw | 4kw | 3kw | 2.2kw | 1.5kw |

| Nail making speed | 180pcs/min | 220pcs/min | 260pcs/min | 320pcs/min | 380pcs/min | 450pcs/min |

| L*W*H | 3.0×1.6×1.75m | 2.5*1.6*1.5m | 2.2*1.6*1.65m | 2.0*1.4*1.4m | 1.7*1.3*1.4m | 1.5*1.3*1.2m |

| Weight | 3 tons | 2.3tons | 2tons | 1.8 tons | 1.45 tons | 1.2ton |

| Output | 3000kg/8h | 2000kg/8h | 1500kg/8h | 800kg/8h | 500kg/8h | 80kg/8h |

Features of South Korea nail making machine

- Hard material: The product is made of sturdy steel and some parts adopt hard alloy or diamond. high hardness and durable.

- Automatic oil supply system: easy operation and maintenance, make the running stable and reliable.

- The high degree of automation: one-click start, automatic running.

- Energy-save and efficiency-high: It can make different size nails, the producing speed is 2-3 times quicker than other machines.

- The machine is made from bearing, which makes the machine less impact and low noise.

- Our machine can feed the raw material automatically.

- South Korea nail making machine can add lubricating oil automatically.

- One model nail making machine can make different sizes of nails.

- Finish product: Twisted nails, tacks, lengthening nails, shaped nails, etc, we can equip different mould according to customers’ demand.

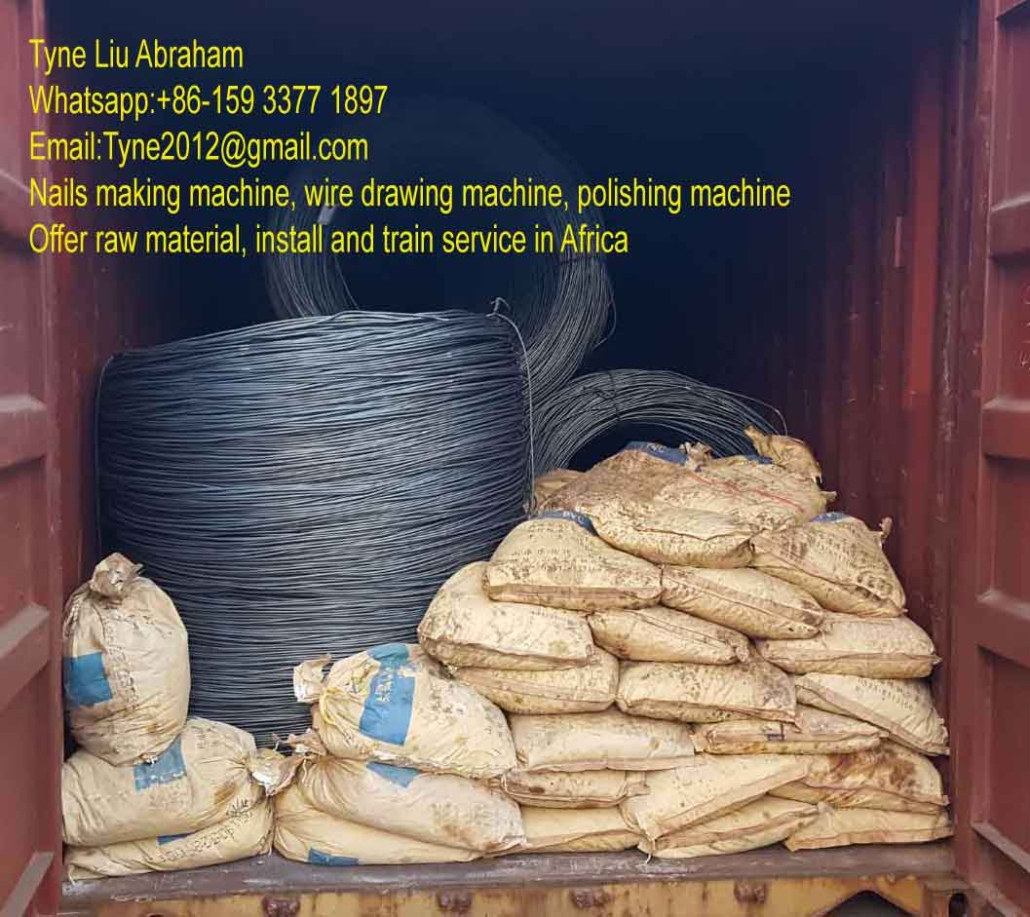

HOW TO GET RAW MATERIAL OF NAIL MAKING MACHINE?

We know, the raw materials of nails making wire in Kenya you cant get. No steel company, no wholesales, no importers. So here is our solution for you.

- Normally, you can buy from the local market or steel company.

- If they can sell low carbon iron wire rod Q195,6.5mm/5.5mm. You can buy and use a wire drawing machine to draw to the thickness you need.

- If better, you can get the thickness nails making wire you need.

- And if local no wire rod and nails making wire, better import from China for any type of them.

- What should import, depend on how is the quantity you want to produce daily output.

- If quantity not much, you can just import nails making wire.

- But if your quantity huge, better buy a wire drawing machine to draw for yourself using.

- Then you can start a Fully automatic nail making machine imported from China and South Korea to make nails.

GUARANTEE AND PAYMENT TERMS TERMS

The guarantee is for 1 year. During this year any broken parts caused by the quality, we can offer you free. After this year we can offer the lowest cost.

Install and training: we will send one engineer to install and training the machine for the customer and need you pay the engineer the salary usd100/day, and the tickets and hotel and food. If the machine price including the install salary the customer just pays for the tickets, hotel, and foods.

Delivery time: 20days after advance payment some times we have stock, then can load container when we get the advance

Payment terms: T/T, 30% in advance, and the balance before delivery.

TESTING OF Z94 NAIL MAKING MACHINE BEFORE DELIVERY

WIRE DRAWING MACHINE FOR SOUTH KOREA NAIL MACHINE

WIRE POINTING MACHINE OPERATING VEDEO

BUTT WELDING MACHINE FOR WIRE DRAWING

GRINDERING MACHINE FOR NAIL CUTTER

HOW MUCH PROFIT IN NAIL MAKING BUSINESS IN AFRICA?

- As for the profit, I think at least USD50/T for the importers,

- And they sell to distributors, who need profit also, right?

- so the reasonable profit is not less USD70/Ton for nails making factory.

- If you catch the right time with lower materials, profit not less than USD100–150/Ton.

If you have more machines, then daily output is not only 1 ton right? so the profit you can imagine now. We are in China, have a branch in Africa, offer train and install service after the sale. If you want to know more about how to earn profit in setting a nail making factory, catch us to further talk. Above are some of the “Questions about Chinese Nail making machine at Quora”. Soon the investment will return back after 5/6 month, then the following days are just profit.

SAPREPARTS FOR Z94 6C WIRE NAIL MAKING MACHINE

- Sharpening dies: this machine is to sharpen the head of steel wire before it is feed into the wire drawing machine, the principle of the drawing machine is that using different size of drawing dies, for example, to draw steel wire of 6.5 mm to 3.8 mm, we can use a drawing die of 3.8mm, sharpen the head of 6.5mm steel wire less than 3.8 mm first, then put the head into the die, then fix the head of the wire to the wire drawing machine, then start pulling. After the wire comes through the die, all the wire becomes the diameter of 3.8mm.

- Nail knife grinder: because after 1-2 days cutting, the nail knife installed on the wire nail making machines will become blunt, then you can use the nail knife grinder to grind the nail knife to make it sharp again.

- Gripping Dies: Machines are provided with round dies having 8 or 10 nail holding grooves

- Cutting Die: For cutting nails and making point after the head & shank are formed Diamond, Chisel, Round, Long or Blunt shaped Points can be made by grinding the tools appropriately

- Header Dies: Used for forming a nailhead Chequered or Plain Heads can be formed with these dies

- Nail Cutter and Die Grinder (supplied with a motor, Emery wheels and Pedestal Stand)

- Optional Accessories: Additional sets of Tooling (Set of Gripping Dies, Cutting Tools, and Header Dies)

- Standard Accessories: Electric Motor, Starter, Belts, One set of Tooling, Wire Stand and Hand Operated Lubricating Pump

- Further DETAILS OF Z94 6C NAIL MAKING MACHINE

AUXILIARY EQUIPMENT FOR SOUTH KOREA NAIL MAKING MACHINE

- Punch pin and nail Moulds.

- Connecting welding machine: in case the wire breaks during drawing, you can use the butt welding machine to weld the broken wire together, then continue the drawing. without this machine, if the wire breaks, you need to sharpen the wire head again and do all things from the start.

- Nail Polishing Drums (with a motor, starter, and belts)

- Wire Drawing Machine (WE OFFER A COMPLETE WIRE DRAWING LINE TO DRAW NAIL WIRE IN VARIOUS DIAMETERS FROM 6 mm or 5.5 mm WIRE RODS)